Pros and cons of using harp mesh wires

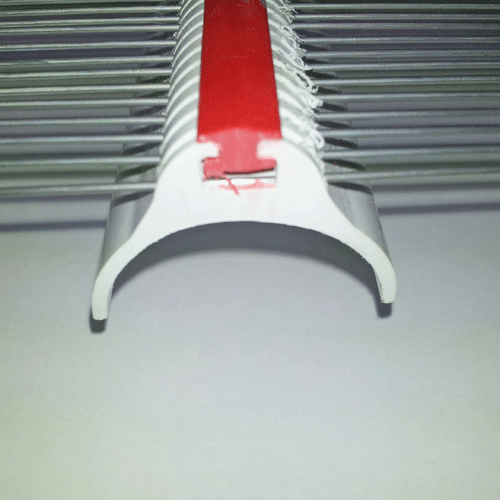

What is a harp screen?

A harp mesh wire is an industrial screen used to separate particles or materials based on size, shape, or other characteristics. It uses a series of parallel wires that are vertically oriented to separate the materials that pass through it. These wires are tensioned and held in place by a frame, which can be made of various materials such as aluminum or stainless steel.

The wire spacing can be adjusted to optimize the screening efficiency for different materials. Harp screens are commonly used to separate and grade materials in the mining, aggregate, recycling, and wastewater treatment industries. They are also used in other industries, such as the chemical, food, and pharmaceutical industries, for separating solids from liquids.

Harp mesh screens are a type of industrial screen product commonly used in the mining and aggregate industries. They use a series of parallel wires vertically oriented to separate particles or materials based on size, shape, or other characteristics. Here are some pros and cons of using harp screens:

Pros:

- High efficiency

Harp screens have a high screening efficiency, which means they can effectively separate materials with minimal loss.

- Durable

Harp screens are typically made from high-strength materials, such as stainless steel, which makes them durable and long-lasting.

- Customizable

Harp screens can be customized to suit specific requirements, such as different wire diameters and spacings, to optimize screening efficiency for other materials.

- Low maintenance

Harp screens are relatively low maintenance and only require occasional cleaning and wire replacement.

Cons:

- Expensive

Harp screens can be more costly than other industrial screens, such as vibrating screens.

- Limited applications

Harp screens are best suited for separating dry materials and may not be suitable for wet or sticky materials.

- Limited size

Harp screens can be limited in scope and may need help to handle large volumes of material.

- Limited by wire size

Harp screens are limited by wire size, which means they may not be able to separate very fine or small particles.

Where are harp mesh screens used?

Harp mesh screens are typically used in the mining and aggregate industries to separate dry materials based on size, shape, or other characteristics. They often process and separate materials such as coal, sand, gravel, and crushed stone. Harp screens can also be used in the recycling industry to separate recyclable materials from waste.

They are also used in other industries, such as chemical, food, and pharmaceutical industries, for separating solids from liquids and other applications where a fine-grade separation is needed. It’s also used as a pre-treatment screen in wastewater treatment plants.

How are harp mesh screens beneficial?

- Versatility

Harp screens can be used in various industries and applications, including mining, aggregate, recycling, and wastewater treatment.

- Cost savings

Harp screens can increase efficiency, improve product quality, and be low maintenance, leading to business cost savings.

- Environmental protection

Harp screens can be used to separate recyclable materials from waste, which can help to reduce the amount of waste sent to landfills and improve overall environmental sustainability.

Last words

Harp screens are a highly efficient and durable industrial screen product commonly used in the mining, aggregate, recycling, and wastewater treatment industries. They use a series of parallel wires vertically oriented to separate particles or materials based on size, shape, or other characteristics.